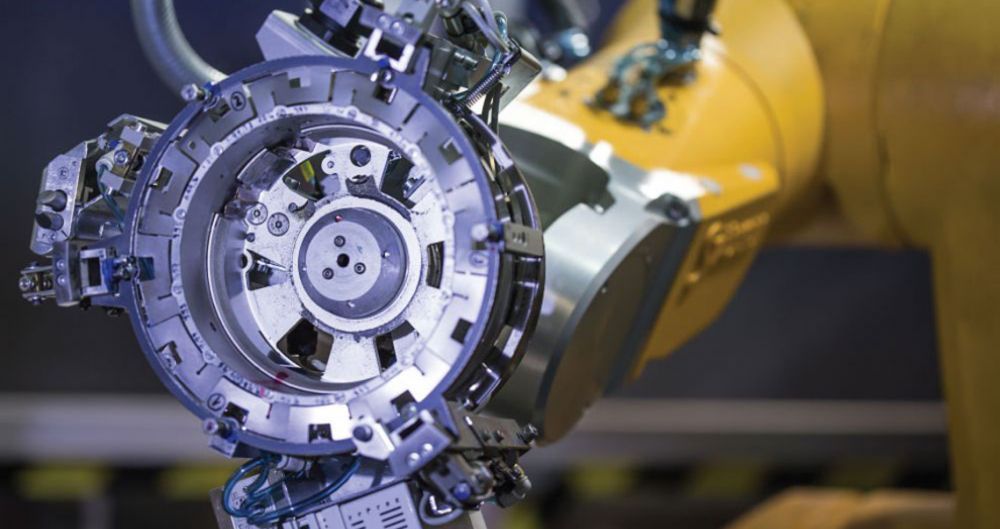

QUALITY

All staff of the company are responsible for the quality of STROJÍRNY POLDI products. The Quality control department, which is completely independent from production, is a guarantee of high level quality in accordance to customer requirements. Activities of this department take place during the production process through a system of receiving, in-process and final inspection where local gauges are used together with portable instruments for the following:

- Hardness measurement by impression and reflection methods,

- Quality inspection of machining,

- Liquid penetrant examination and ultrasonic inspection

Our own mechanical and metallographical laboratories may possible be used. The measuring is highly advantageous.

MECHANICAL LABORATORY

Instrumentation of the Mechanical Laboratory:

- Testing machine for determination of tensile and compressive strength of material

- Impact testing machine Charpy with gradient energy 300 J

- Vickers HPO 250 hardness tester

- Brinell AB R. hardness tester, Almkvist, type ALPA

- Rockwell hardness tester, Armalit, type TK

- Vickers micro hardness tester, type PMT3, test load 1 – 200 p

- Equopen hardness tester

- Two laboratory furnaces with temperature range up to 1200 °C

METALLOGRAPHICAL LABORATORY

Instrumentation of the Metallographical Laboratory:

- Neophot 32 optical microscope

- Dino-Lite AM 413T digital microscope

- Dino-Lite AM 313 digital microscope

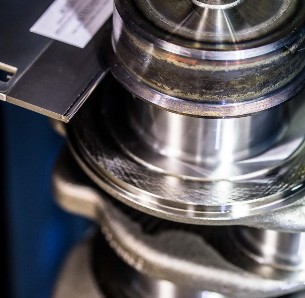

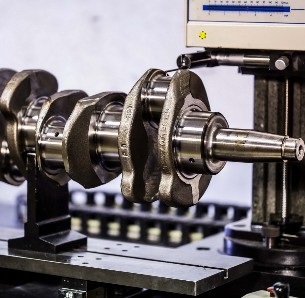

MEASUREMENT CENTER

Instrumentation of the Measurement Center:

In order to assure measurement of the company´s product range and calibration of the applied measuring instruments, the measurement center is furnished, besides common measuring instruments, also with measuring devices from leading companies in this area.

- ADCOLE 1200 SH

- Taylor-Hobson TALYROND 400

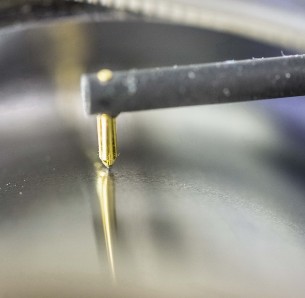

- Taylor-Hobson TALYSURF FTS 2 – PNEUMO

- Taylor-Hobson SURTRONIC 3+

- Profile projector HORVER 420

- Three-coordinate measuring instrument SYMETRIC 954 DCC

- Three-coordinate measuring instrument MERLIN-IMS

- Universal length measuring ZEISS

- The meter gauge blocks MKM 3