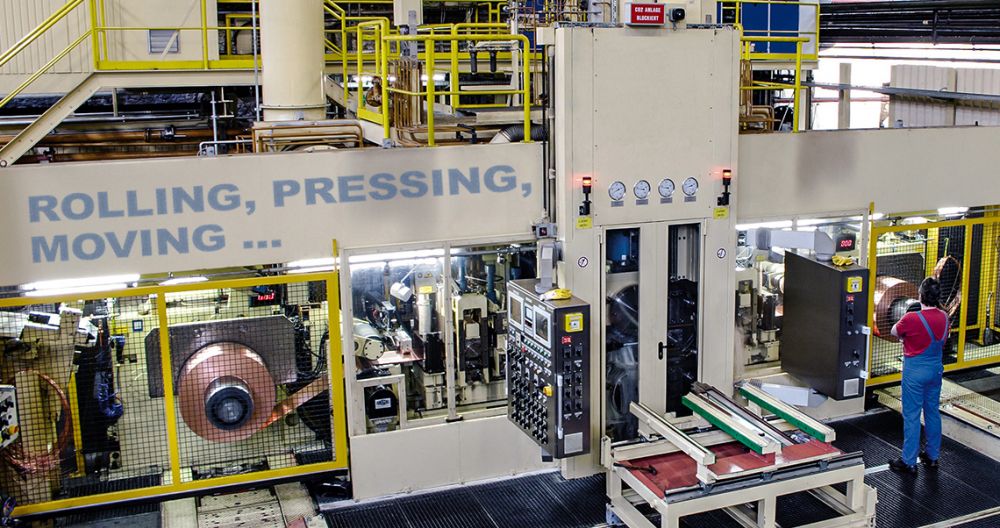

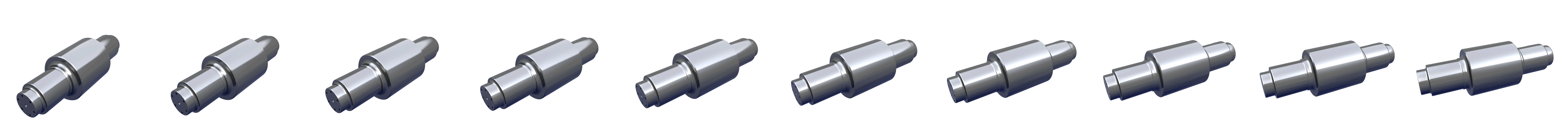

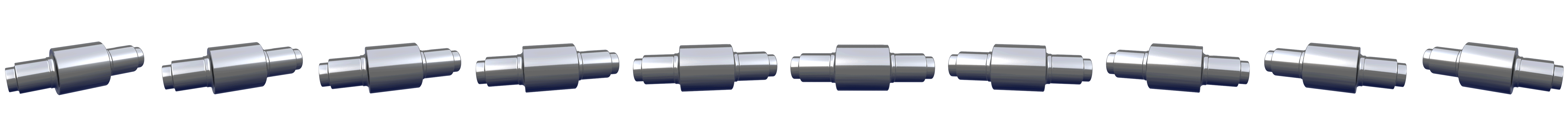

FORGED ROLLS

POLDI Steel Works was established in 1889. The mechanical engineering part of production dates back to the 1890’s.

The production of forged rolls commenced in 1910.

Since then the technology of roll production has been developed and perfected within the plant. Today’s product is based on generations of experience as well as modern advanced production technology.

In STROJÍRNY POLDI, a.s., rolls for cold rolling are made from forgings supplied by companies which meet stringent quality requirements. For the manufacturing of rolls, either steel from electric arc furnaces, vacuum degassed, or possibly steel made in ladle furnace by secondary refining can be used. For special applications, electro-slag re-melted steel or vacuum re-melted steel can be used.

In order to achieve the best properties for the rolls, our own know-how is used because heat treatment has a decisive influence on roll properties. The roll barrel is hardened in a medium-frequency induction hardening machine. A machine for induction hardening of roll bearing seats is also available.

In order to fully meet requirements, our forged rolls are machine finished and ground to the Customer’s dimensions and surface quality specifications.

DOWNLOAD

|